News - May 2023 - Legal Update

News: High-rises must be registered

The system has gone live for Accountable Persons to register high-rise residential buildings as required by the Building Safety Act 2022. This affects all high-rise residential buildings 18 metres tall or higher, or at least 7 storeys tall, with two or more residential units and is to be completed by 1st October 2023.

Key steps to compliance:

1. Use the HSE link below to register a building.

Further information:

https://press.hse.gov.uk/2023/04/12/registration-of-high-rise-residential-buildings/

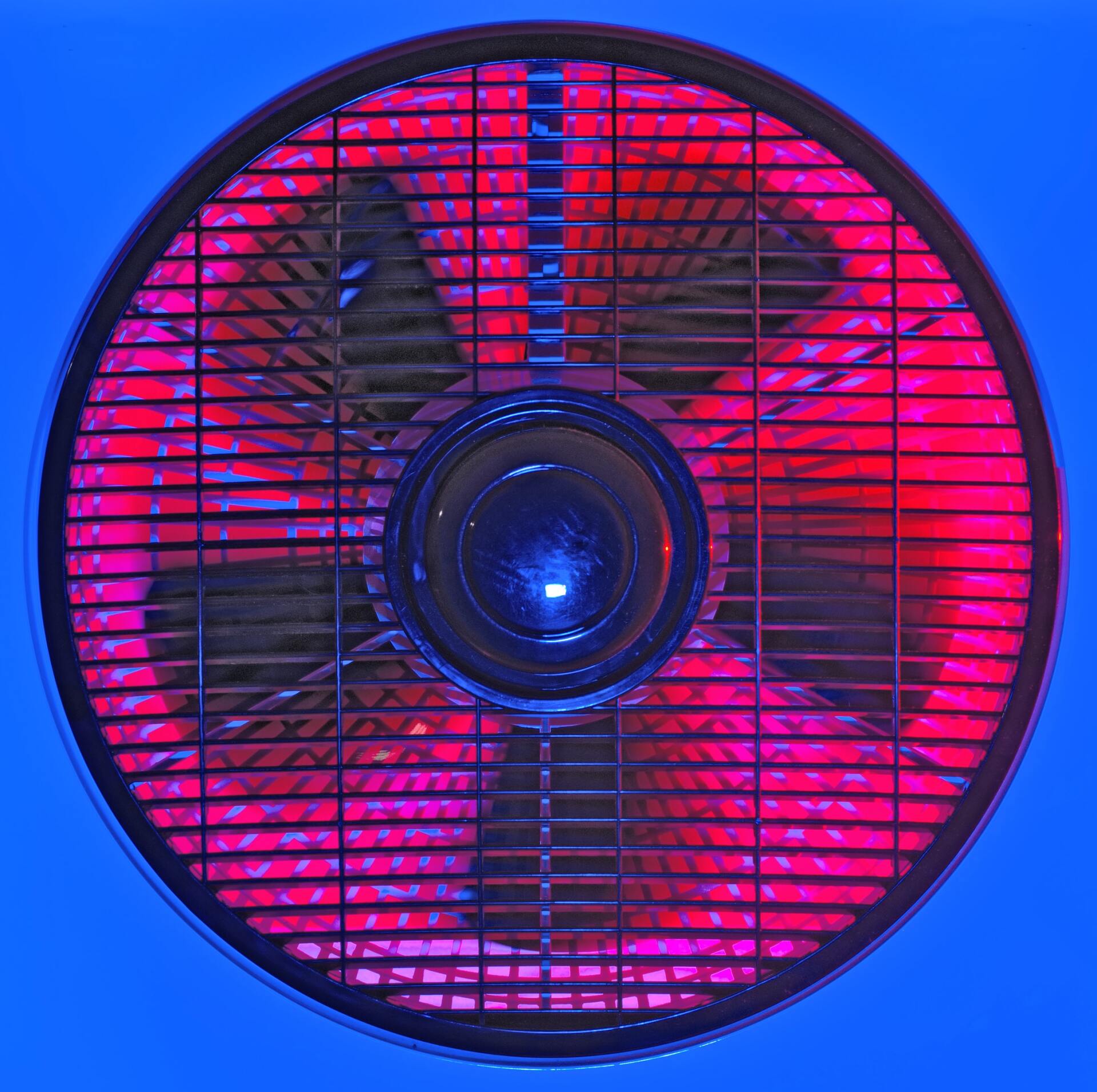

News: Floor gratings

This HSE alert aimed at wind farms and off shore platforms is worth reading if you have floor grating systems. The HSE’s warning is that it’s found several industrial polymer floor grating systems to be improperly secured carrying a risk of collapse or tripping accidents

Key steps to compliance:

1. Check that fasteners used to secure sections in place have been installed as per the original equipment manufacturer’s guidance

Further information:

https://www.hse.gov.uk/safetybulletins/floor-grating-systems.htm

News: Wood dust exposure

Management of exposure to wood dust remains a top priority for the HSE. Joinery Limited has been fined after being caught in one of the HSE’s campaign visits. Thick layers of wood dust were left lying because the extraction system was not connected to all machines.

Key steps to compliance:

1. Local Exhaust Ventilation (LEV) must be in place and be effective.

2. LEV must be inspected and tested by a competent person every 14-months.

3. Cleaning regime be in place to remove excess dust.

4. M-Class vacuum to be used to clean up dust – Do not use brooms to sweep up dust.

5. Risk assessment and safe system of work must be in place for the work equipment.

6. Work equipment is inspected for signs of damage prior to being used.

7. Staff are trained and competent in the use of equipment.

Further information:

Case law: £600,000 fine for fork lift truck accident

AkzoNobel Packaging Coatings Limited has been fined £600,000 after a worker’s leg was crushed by a forklift truck as he stood on a pedestrian crossing. It seems that poor practices had crept in and been allowed to continue unchecked.

Key steps to compliance:

1. Risk assessment and safe system of work for forklift operations.

2. Pedestrians and forklift movements are separated effectively.

3. Staff are trained and competent in the use of a forklift.

Further information:

https://press.hse.gov.uk/2023/04/03/company-fined-after-workers-leg-crushed-by-forklift-truck/

Case law: Man killed by metal grab

A manufacturer of concrete products has been fined £1 million after a 24-year-old man was crushed in a grab which was the wrong accessory for the lifting task in question. The HSE found that there was a lack of risk assessment and that both the grab and a fork lift truck being used at the time were in poor condition.

Key steps to compliance:

1. Risk assessment and safe system of work are in place for the work equipment.

2. Work equipment being used is suitable for the task.

3. Work equipment is inspected for signs of damage prior to being used.

4. Staff are trained and competent in the use of equipment.

Further information:

Case law: Cut and paste is not an option!

A hotelier downloaded risk assessment to pass as his own. A Swindon hotelier received little sympathy from inspectors after attending an interview to discuss lack of compliance with improvement notices and attempting to pass off a fake risk assessment. He has been fined £8,000.

Key steps to compliance:

1. Make sure your risk assessments and other health and safety documentation accurately reflect your operations.

2. Regularly review your documents to ensure that they remain accurate.

3. Work with your health and safety advisor to ensure the risk assessment is suitable and sufficient.

Further information:

Case law: Three-section ladder used as roof-ladder

Mackenzie Hotels Ltd has been find in connection with an accident caused by inappropriate use of a ladder for roof-work which needed an alternative solution.

Key steps to compliance:

1. Risk assessment and safe system of work are in place for the work equipment.

2. Work equipment being used is suitable for the task.

3. Work equipment is inspected for signs of damage prior to being used.

4. Staff are trained and competent in the use of equipment.

Further information:

Case law: Lifting operation went wrong

A principal contractor and cladding contractor have shared the dock in a case which followed a lifting failure with a Structured Insulated Panel (SIP). The accident involved a sub-contractor of the cladding contractor and both parties who should have overseen the work took the blame for the subsequent accident.

Key steps to compliance:

1. Ensure all lifting operations are completed by competent contractors.

2. Ensure suitable selection and appointment of contractor system is in place.

3. Check the safe systems of work that are to be followed by the sub-contractors working on a project are suitable and sufficient. Ensure there is a paperwork trail in place that identifies that checks have been completed.

4. Have suitable and sufficient site supervision arrangements in place.

5. A lifting plan must be in place for all lifting operations.

Further information:

Case law: Keep your site secure

Poor security of a construction site next to a playpark in Glasgow was the cause of children gaining access a court has heard. A ten-year-old child was killed when he fell within a manhole on the surface water management project. R.J. McLeod (Contractors) Limited pleaded guilty to breaching Section 3(1), Health and Safety at Work etc. Act 1974 and was fined £800,000 plus a victim surcharge of £60,000

Key steps to compliance:

1. Ensure that there is a suitable barrier/fence around your site to prevent unauthorised access.

2. Place suitable “Warning Construction Site” signs on the fencing.

3. Check the fence regularly for signs of damage.

Further information:

You want to stay up-to-date?

Join our mailing list!