May 2024 - Legal Update

News: Approved Document B

A new version of the fire safety guidance to the Building Regulations 2010 has been published. The updated Approved Document B begins with a list of amendments made to it including new requirements for means of escape from high rise buildings.

The Building Regulations apply to new builds and alterations.

Further information:

https://assets.publishing.service.gov.uk/media/66054cc0f9ab41001aeea490/AD_B_amendment_booklet.pdf

News: Free Webinars from HSE

The HSE is giving a webinar on 15 May 2024, ‘Duty to manage asbestos in buildings.

There’s also an event on 23 May: ‘Musculoskeletal disorders (MSD) risk management tools: What are they and how should they be used?’

Further information:

https://solutions.hse.gov.uk/health-and-safety-training-courses/duty-to-manage-asbestos-in-buildings

https://williamslea.zoom.us/webinar/register/WN_g0OFyyH_QGC1bkajzBJ9sw

News: Fire and Rescue Data

Fire Rescue Services in England attended 592,996 incidents in 2023, a decrease of 5.6% in comparison the previous year. Fires accounted for 24% of incidents attended, fire false alarms 42% and non-fire incidents 34%.

Further information:

News: First Aid guidance updated

Updates have been made to the HSE’s ‘First aid at work: Guidance on regulations’ (L74) and ‘Selecting a first aid training provider: A guide for employers.

Further information:

https://www.hse.gov.uk/pubns/books/l74.htm

https://www.hse.gov.uk/pubns/geis3.htm

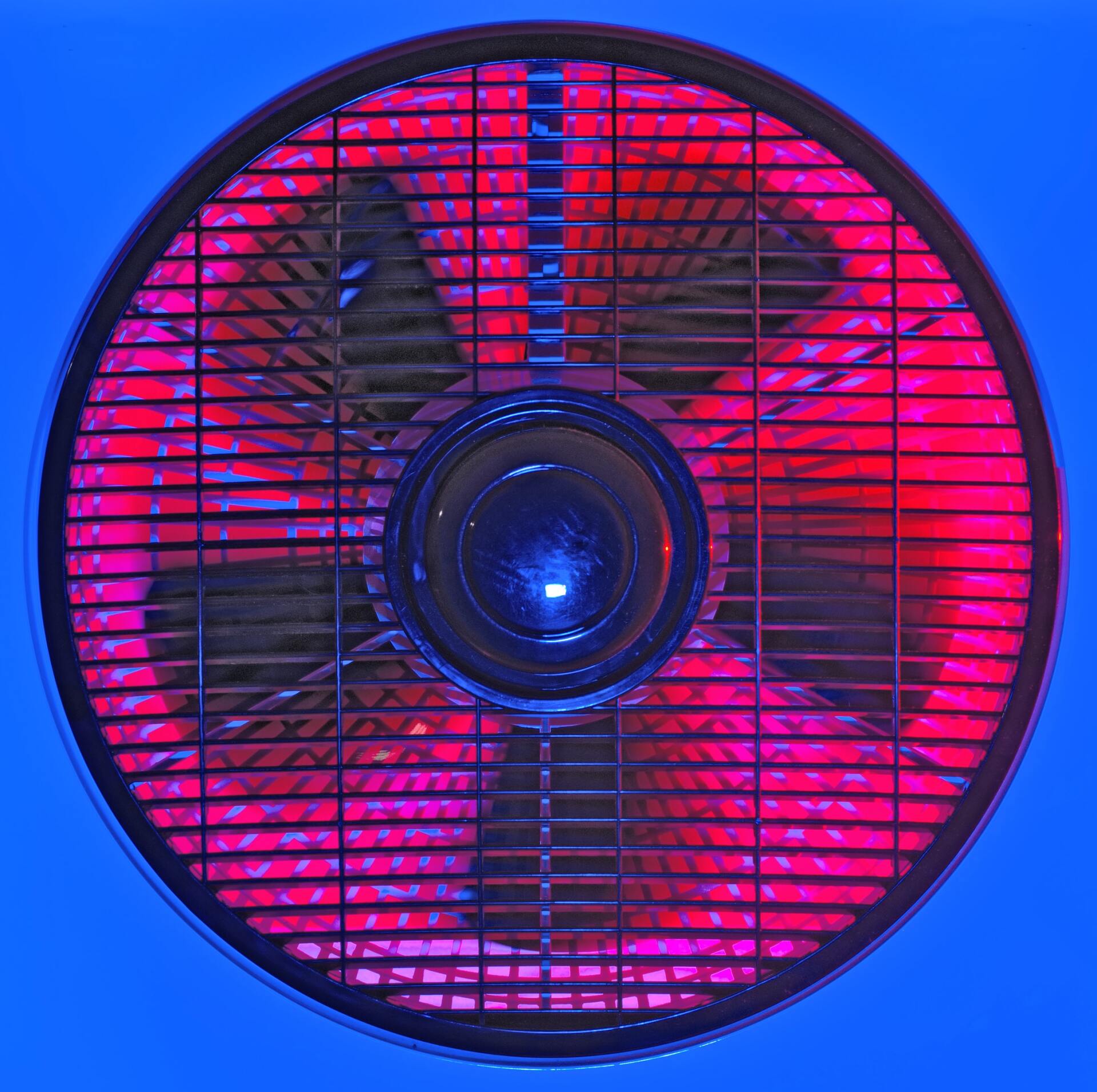

News: Evaporative cooling systems

HSE guidance, 'The control of legionella bacteria in evaporative cooling systems' (HSG274: Part 1), has been updated. It includes clearer advice on testing of pH and biocide levels.

Further information:

https://www.hse.gov.uk/pubns/books/hsg274.htm

News: RIDDOR guidance improved

- more direct links to guidance on types of reportable incidents to help determine whether a report is required

- improved guidance on who should and should not report under RIDDOR

- improved guidance on what is meant by a ‘work-related’ accident

- information on when an occupational disease is not reportable

- increased clarity on when an ‘over-7-day’ absence should be reported

Further information:

https://www.hse.gov.uk/riddor/?utm

Case law: Fatally crushed under scissor lift

A court has heard how a broken locking mechanism appears to have prompted a baggage handler to switch sides of a platform whilst working by an aircraft. In doing so he stepped through beneath the platform when it was unfortunately lowered and crushed him. There was no detector to stop the machine being lowered. It was also observed that had the machine been in good repair, the accident would not have happened.

Steps to compliance:

- Work at height must be planned and managed so that falls are prevented, and steps takes to prevent falls must be documented.

- Appropriate work equipment must be used i.e. cherry picker or tower scaffold.

- Staff must be trained and deemed competent to complete the works.

Further information:

https://press.hse.gov.uk/2024/04/17/aviation-company-fined-after-worker-death-at-heathrow-airport/

Case law: Worker struck underground cable

MHS Homes has been fined £528,000 after an employee repairing a fence post inadvertently struck an underground cable, suffering burns to his face. It appears from the HSE’s case summary that the company had none of the expected precautions for safe digging in place.

In court, the company pleaded guilty to breaching Regulation 16(2), by virtue of non-compliance with Regulation 25(4), the Construction (Design and Management) Regulations 2015. The company was fined £528,000 plus £4,122 in costs.

Further information:

Case law: Exposed to unacceptable levels of wood dust

A manufacturer has been prosecuted for breaching Regulation 7(1), Control of Substances Hazardous to Health Regulations 2002 after inspectors found that workers were exposed to excessive amounts of wood dust. The company had received previous advice from inspectors but it hadn’t been taken, and there were large quantities of dust around the machines. It was fined £14,700 plus costs of £4869.

Case law: Exposed to unacceptable levels of wood dust

Steps to compliance:

1. Local Exhaust Ventilation (LEV) Must be in place and be effective.

2. LEV must be inspected and tested by a competent person every 14-months.

3. Cleaning regime to be in place to remove excess dust.

4. M-Class vacuum to be used to clean up dust – Do not use brooms to sweep up dust.

5. Risk assessment and safe system of work must be in place for the work equipment.

6. Work equipment is inspected for signs or damage prior to being used.

7. Staff are trained and competent to use the equipment.

Further information:

https://press.hse.gov.uk/2024/04/03/company-fined-after-hse-inspection-finds-wood-dust-failures/

Case law: Letting agent fined over fire trap

After a resident complaint about a blocked escape route at a shared house, fire officers inspected, finding a large shipping container blocking an escape route, as well as a padlocked door. Within the house they found various breaches in the structure which would have given very little time to escape in the event of fire.

Further information:

Case law: Asbestos disturbed during demolition

After inspectors followed up reports of unsafe work at height, they found a site covered in asbestos waste. It became apparent that the developer had received an asbestos survey report but ignored it and had the materials stripped out by untrained workers.

Although the business Eye Track Limited was fined, it was the director, Selcuk Pinarbasi, who received the higher penalty. He pleaded guilty to breaching Section 3(1) by virtue of Section 37(1), Health and Safety at Work etc. Act 1974. He received a custodial sentence of 20 weeks, suspended for 12 months, was fined £75,000 and was also ordered to pay costs of £18,783.

Steps to compliance:

1. Stop works immediately and halt any activates in the area where asbestos has been disturbed.

2. Isolate the area and use barriers where required.

3. Engaged licensed asbestos contractors to safety remove any asbestos on site.

Note. To prevent incidents such as this, asbestos refurbishment surveys must be completed prior to works commencing.

Further information:

https://press.hse.gov.uk/2024/04/25/company-and-director-fined-after-workers-exposed-to-asbestos/

Case law: Unguarded table saws

Steps to compliance:

1. Ensure all maintenance works are planned and completed by a competent person.

2. Safe systems of work to be documented.

3. Control measures such as permit to work to be used.

Further information:

https://press.hse.gov.uk/2024/04/17/shipping-services-company-fined-after-worker-loses-finger/

Case law: Power was not isolated before maintenance

A company has pleaded guilty to a safety offence after an accident in which an employee lost a leg. He was caught in machinery which was used to put compost into trays.

There were inadequate risk assessments for cleaning, and no isolation nor safe operating procedures. Howdens Enterprises Ltd pleaded guilty and was fined £73,333 plus costs of £7,522.

Further information:

You want to stay up-to-date?

Join our mailing list!